Embracing the Future Through In-House LiDAR Capabilities

Long before 3D modeling was commonplace in the engineering world, Jōb Industrial Services embraced it when we were founded in 2005. Since then, we’ve developed in-house LiDAR capabilities and have prioritized utilizing new technology as it comes along in order to better serve our clients. At Jōb, integrating in-house LiDAR technology with our engineering services has propelled projects to new heights and redefined the standards of efficiency and accuracy within our 3D modeling, design and construction processes.

What is LiDAR and How Does It Work?

LiDAR stands for Light Detection and Ranging. While sonar uses sound waves and radar uses radio waves to measure distance, LiDAR mapping uses light from a laser. The most accurate tool of the three, laser light is monochromatic, coherent, and directional, unlike white light. This means that laser light contains one wavelength, and all photon movement is coordinated, resulting in an extremely narrow, concentrated, high-intensity beam of light.

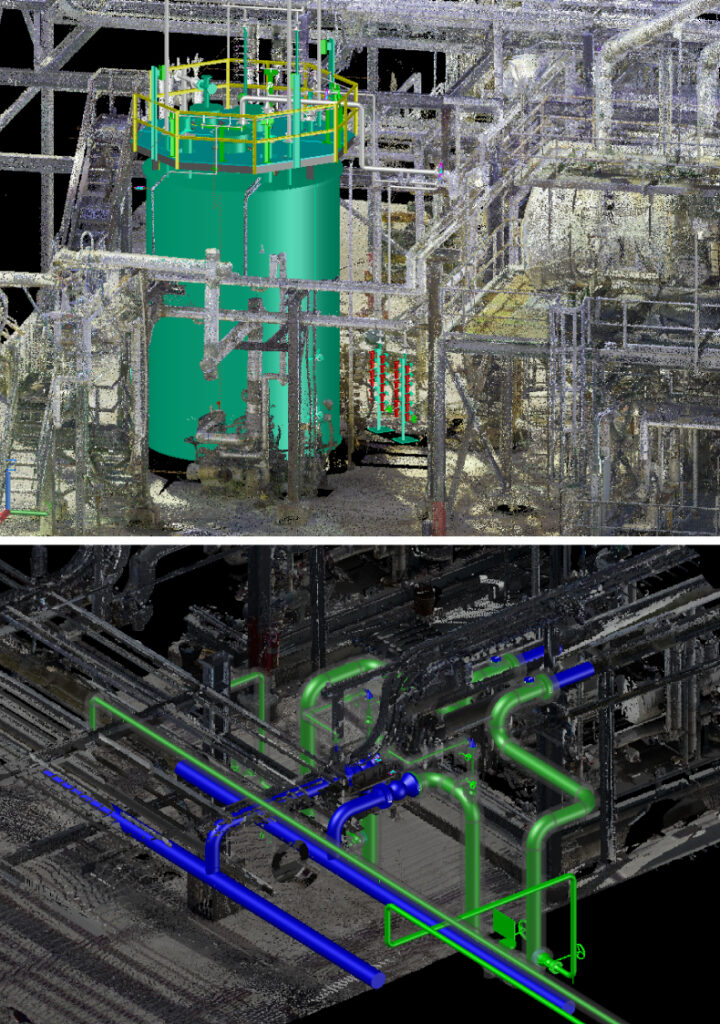

So, how is LiDAR used to create such precise 3D images? A LiDAR scanner emits a laser pulse and measures how long it takes for the laser beam to return to the sensor. It creates a variable distance between objects, getting a sense of the terrain and its surroundings. LiDAR sensors also measure the color and intensity of the pulse when it’s reflected back, identifying the material the object is made of. After the data is collected, it translates into a 3D point cloud, allowing the images to be processed by a computer to determine the object’s measurements.

How Jōb Uses LiDAR

Jason Parker, Jōb’s LiDAR & digital scanning manager, has been working with LiDAR technology for over 20 years. His experience is vast, from small projects such as pump outlets to large-scale projects scanning entire facilities. In fact, Jason even played a key role in pioneering the transition from black-and-white to full-color points. Through Jason’s and our digital scanning team’s expertise, Jōb Industrial Services integrated in-house LiDAR capabilities into our design, engineering and construction processes.

“Our in-house LiDAR technology allows for a far more efficient and effective scanning process,” Jason said. “In the past, a single scan would typically take 10-15 minutes. Now, we can complete a scan in about 3-5 minutes, saving our clients ample time and money throughout a project’s life cycle.”

Not only does Jōb’s in-house LiDAR technology save time during the data collection process, but during the retrieval process as well. With in-house LiDAR capabilities, Jōb provides our clients with their data in half the time, as opposed to waiting on a third-party vendor. We also utilize our team’s extensive experience to provide clients with a holistic view of their projects rather than focusing on one engineering discipline.

“Jōb takes a consultative approach to digital scanning,” Jason said. “We look beyond the problem at hand and dig more deeply to assess a system’s civil, structural, electrical and mechanical components to prevent future issues. Other companies may solely focus on the task in front of them. At Jōb, we pride ourselves on creative problem-solving and not missing the forest for the trees.”

Once the scanning is complete, we can hit the ground running in order to provide personalized solutions for our clients. By retrieving all the data we need in one trip, we don’t have to hit pause on our client’s project. Jōb’s use of in-house LiDAR technology within civil, structural, piping/mechanical, electrical and other engineering disciplines lends itself to fewer field modifications and change orders throughout a project’s life cycle, improved safety through fewer field visits to take measurements and the highest levels of efficiency and accuracy for our clients. The bottom line? We save our clients plenty of time and money while getting the job done.

LiDAR in Action

When a Utah mainstream gas production facility’s black wax pumps were within a containment area, they came to Jōb’s LiDAR scanning team to mitigate the risk of a potential fire hazard. We went out, scanned the area for the client and relocated the pumps away from the containment area while still allowing for proper gravity flow.

“The client was thrilled with the speed of it,” Jason said. “The client had gone out a week before with another company and it took them the better part of the day to get 42 scans of a different area in the facility. The Jōb team went out there for two hours, and we got about 30 scans for the client. It got him back in the office faster, and he was really grateful.”

A mineral processing plant had been struggling with a particular project for quite some time before Jōb scanning entered the picture. The client couldn’t decide how best to tie small bore piping together and add level indicators due to the angle at which it converged. Jōb traveled to the facility, scanned the area, and within a couple of weeks, Jōb helped the client to successfully complete the project.

Jōb’s LiDAR scanning team came to a New Mexico diesel production facility’s aid when they needed to reroute a new 4-inch line into two of their units. The client’s biggest obstacle? The pipe had to be run through a fully loaded pipe rack, and there was a lack of open pathing. Jōb used LiDAR technology to find the best path within the piping system and utilize best practices in order to create a new bypass for the system.

In a world where technology is constantly evolving, Jōb’s ability to adapt to and embrace new technologies allows our clients in the refining, petrochemical, midstream, mining and industrial spaces to have a competitive advantage within their respective industries. By utilizing in-house LiDAR technology, Jōb Industrial Services provides customized solutions for our clients in significantly less time for a lower cost.

At the end of the day, our main goals are to provide the highest quality services to achieve the highest amount of client satisfaction. With our in-house LiDAR capabilities, we’re able to do just that. Reach out today to see how our LiDAR capabilities may benefit your project.